UNILIN, Insulation Division

- Waregemstraat 112 - B-8792 Waregem, Belgium

T

+32 (0)56 73 50 91 –

F

+32 (0)56 73 50 90

–

Web

www.unilininsulation.comTrade Registry Courtrai no. 87.153 – VAT no.: BE 0405 414 072

3

3. ATTACHMENT TECHNIQUES

1. Mechanical attachment

u

THERM

Flat Roof

insulation boards can be attached mechanically.

The following preconditions have to be observed in the application of fastening elements.

The fastener must be positioned vertically.

A mechanical attachment is always carried out in combination with a washer.

The head of the fastener must lie at least below the level of the washer.

Washers may not be visibly deformed.

Washers may not have penetrated the insulation material for more than 3 mm, and the laminating layer may not show any visible damages.

The washers may not be attached loosely.

For all zones on the roof surface, the effectively required number of fasteners must be determined in function of the wind load, and in conformity

with the regulations of the manufacturer of the roof waterproofing.

Additional comments:

When using screws, the rotational speed of the screwdriver must conform to the guidelines provided by the supplier of the fasteners.

It must be possible to set the depth of the stroke of the attachment tool.

2. Cold glueing

Cold glueing is carried out over the full surface, or the glue is applied in even strips on the underground. Dependent on the wind load, more or

less glue will have to be applied.

At the edges and at the corner areas of the roof, and in case of strongly exposed roofs, a larger surface of a glue must be applied, or the insulation

boards must be secured mechanically in addition or be provided with ballast.

The manufacturer of the glue must provide information on the suitability of his product.

The application of the glue must always be carried out according to the regulations of the manufacturer.

Double-layer glueing of the insulation boards is possible

.

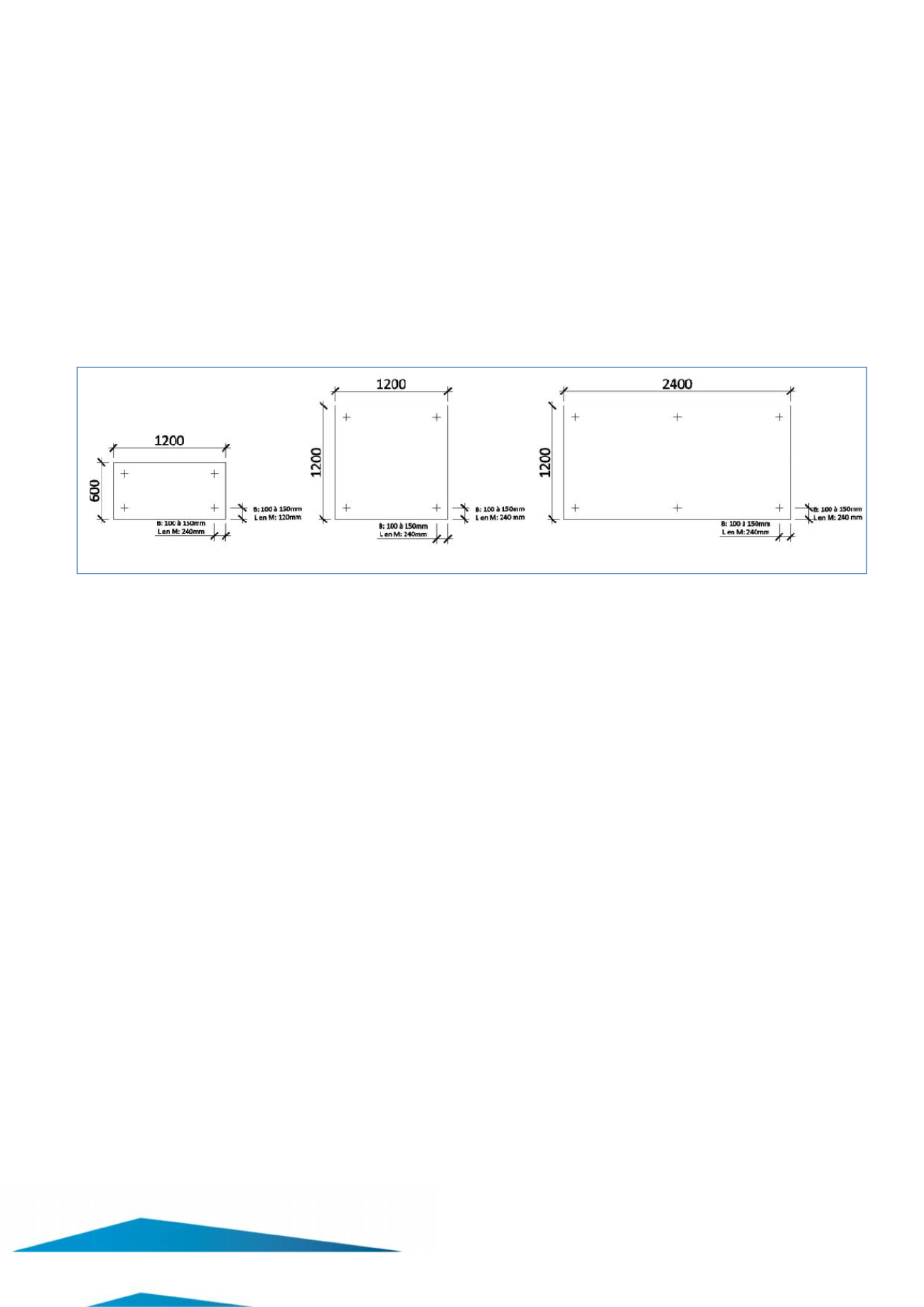

UNILIN recommends that a maximum size of 1200 mm x 1200 mm is used, if the insulation boards are to be attached with glue.

3. Glueing with synthetic glue

For 1-component glue, it must be possible to foam up the glue, which is stimulated amongst others by the air humidity and ambient temperature.

The installation usually takes place by glueing sections (strip-by-strip) according to the instructions of the glue manufacturer. The use of synthetic

glues leads to rigid or elastic connections, which prevents "walking" of the insulation boards.

The manufacturer of the glue must provide information on the suitability of his product.

UNILIN recommends that a maximum size of 1200 mm x 1200 mm is used, if the insulation boards are to be attached with glue.

4. Hot glueing

For reasons of technical compatibility, only insulation boards with a bituminous glass fleece facing can be used for hot glueing.

UNILIN recommends that a maximum size of 1200 mm x 1200 mm is used, if the insulation boards are to be attached with glue.

u

THERM

Flat Roof BG

roof insulation boards are resistant to temperatures of up to 250°C, which means they can be attached to the subsurface

with hot bitumen over the entire surface.

In case of partial glueing, every insulation board must be solidly glued for at least 50% to the subsurface.

Glueing according to a distribution of the glue in a serpentine pattern is reliable. Glue spot attachment is not recommended in this case.

The quantity of hot bitumen glue is dependent on the subsurface and usually amounts to an average of 1.5 kg/m². The processing temperature

lies at 180°C.